Remember the first time you saw a miniature knight on a tabletop, detailed enough to be a museum piece? Every glint off the armour plates, every texture in the leather, was perfectly visible. This is no longer the exclusive domain of industrial mass production; it’s the magic that resin 3D printing brings to every creator. As we advance into 2025, this desktop revolution is evolving at an unprecedented pace, making ultra-high-precision, personalized manufacturing more accessible than ever.

Whether you’re a veteran tabletop gamer, a model enthusiast, or a designer eager to turn digital concepts into physical objects, this guide will take you deep into the core of 2025’s resin 3D printing landscape. We’ll explore how to choose your ultimate tool and master this incredible creative force.

2025 Tech Trends: Beyond the Resolution Race

There was a time when conversations about resin 3D printers revolved around two key specs: resolution and build volume. By 2025, the competition will have moved beyond a simple numbers game into a new era of smarter, more efficient, and user-friendly technology.

First, let’s still pay respect to resolution—the pixel size on the XY axis that dictates a model’s surface smoothness. Mainstream machines in 2025 have pushed printing precision below 35 microns, with 20 microns becoming standard for high-performance models. This means layer lines are now virtually invisible to the naked eye. But the real game-changers are elsewhere:

- A Revolution in Speed: Traditional layer-by-layer curing is being replaced by faster technologies. Some brands, for instance, use a synergistic optimization of smart light sources and proprietary resin formulas to drastically cut down exposure time per layer. The advent of high-speed modes has slashed the time to print a standard-sized miniature from several hours to under an hour.

- Intelligent Levelling and Failure Prevention: High-end 2025 machines are packed with sensors. They can auto-level the build plate, monitor the resin vat’s temperature and fluid levels in real-time, and even use AI algorithms to detect potential print failures and pause the job in advance, saving you precious time and materials. This increased automation significantly lowers the barrier to entry for beginners.

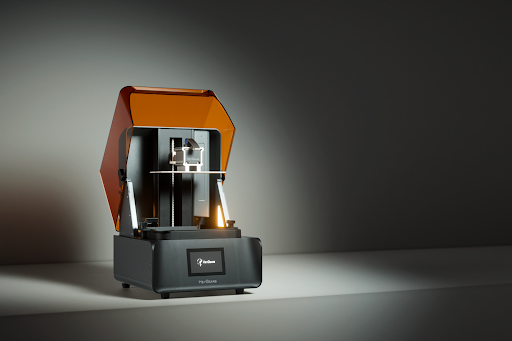

In the fields of rapid prototyping and precision miniatures, we’ve noticed leading brands in 3D printers—HeyGears consistently focus on combining high automation with exceptional print quality. Their machines often integrate a closed-loop solution from modelling to post-processing, making them ideal for design studios and small manufacturing units that demand both efficiency and quality to quickly turn ideas into tangible, high-fidelity objects.

Choosing Your 2025 Dream Machine: A Practical Guide

Faced with a dazzling array of options, how do you make a smart choice? Start by asking yourself a few key questions.

First, define your core need. Are you primarily printing 28-32mm tabletop miniatures, or do you need to create larger-scale statues and props? The former demands extreme detail but has a small build volume requirement; the latter needs a machine with a generous build volume that can maintain stability over large print areas.

Second, evaluate how much you value convenience. Traditional resin printing involves a lot of dirty work, like pouring resin, cleaning the machine, and handling IPA for washing. In 2025, integrated, all-in-one solutions will be a major trend.

The Hidden Costs: Post-Processing and the Ecosystem

The price of the printer itself is just the tip of the iceberg. The real long-term investment lies in post-processing equipment and consumables. You need to consider:

- Washing and Curing Stations: These are practically standard equipment. The 2025 generation of wash stations is smarter, featuring automatic agitation and filtering to extend the life of your cleaning alcohol. Curing stations now use multi-angle UV arrays to ensure uniform curing and prevent warping.

- Resin Materials: This is the soul of your finished product. The 2025 resin market is more diverse than ever. Beyond standard high-detail resins, you’ll find specialized easy-to-paint resins with superior surface adhesion, high-toughness unbreakable resins, and even specialty materials that are transparent, fluorescent, or flexible. Choosing a brand with an active community and a wide selection of consumables means your future creative possibilities are virtually limitless.

Here, HeyGears 3D Printers are working to simplify the complexities of post-processing through its integrated hardware and software ecosystems, offering a seamless experience from print to finish. This is a highly attractive value proposition for users who want to focus on creation, not tedious maintenance.

Mastering Your Creative Workflow From File to Finish

Once you have a powerful tool, how do you get the most out of it? A complete workflow is essential.

- Create or Acquire a Model: You can download countless stunning models from platforms like Thingiverse and MyMiniFactory, or you can sculpt your own unique creations using software like ZBrush or Blender.

- Slicing and Supports: This is a critical prep stage. Use your printer’s native software or a third-party slicer like Chitubox or Lychee to slice the 3D model into layers the printer can read. Adding supports to your model’s overhangs is non-negotiable—without them, the print will fail. By 2025, the AI-powered auto-support features in slicers have become incredibly sophisticated, significantly reducing manual adjustments and boosting success rates.

- Printing and Post-Processing: Once you hit print, you can look forward to seeing your creation come to life. After the print is done, carefully remove the model, wash away uncured resin in a wash station using alcohol or a dedicated solution, and then place it in a curing station for the final hardening. Finally, carefully remove the supports, sand any marks, and begin painting. Your masterpiece is born.

Conclusion: Embrace the Personal Manufacturing Revolution

In 2025, resin 3D printing has become a powerful creative medium. It has democratized precision manufacturing, empowering everyone to become the creator of their own miniature worlds. Technological advancements are continuously lowering the barrier to entry while raising the ceiling for quality.

Whether your passion lies in the serried ranks of a Warhammer army, the exquisite form of an anime figurine, or the rapid iteration of a product design, there has never been a better time to dive in. Take this guide, take that first brave step, and start exploring and creating. Let your imagination solidify into a timeless work of art through the magic of resin.